Blog 2: Gears

- darelsuen

- Nov 19, 2022

- 4 min read

Updated: Nov 20, 2022

In this page, I will describe:

1. The definition of gear module, pitch circular diameter and the relationship

between gear module, pitch circular diameter and number of teeth.

2. The relationship between gear ratio (speed ratio) and output speed, between

gear ratio and torque for a pair of gears.

3. How I can design a better hand-squeezed fan, including the sketches

4. How my practical team arranged the gears provided in the practical to raise

the water bottle, consisting of:

a. Calculation of the gear ratio (speed ratio)

b. The photo of the actual gear layout.

c. Calculation of the number of revolutions required to rotate the crank

handle.

d. The video of the turning of the gears to lift the water bottle.

5. My Learning reflection on the gears activities.

1. These are the definition of gear module, pitch circular diameter and the relationship between gear module, pitch circular diameter and number of teeth:

GEAR MODULE

Gear 'module' is a unit that indicates the size of a gear. It is the ratio of the diameter of the gear divided by the number of teeth. It can be expressed by the below equation:

Where m is the gear module, d is the reference diameter of gear and N is the number of teeth on gear.

Pitch Circular Diameter

Pitch Circular Diameter is the imaginary circle that passes through the contact point between two meshing gears. It represents the diameters of two friction rollers in contact and moves at the same linear velocity.

Relationship

The relationship between gear module, pitch circular diameter and the number of teeth is that PCD (d) could be obtained by multiplying module (m) and the number of teeth (z). The formula is expressed as d = m x z.

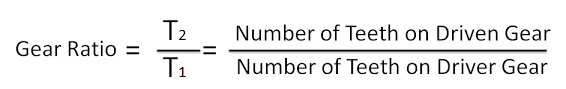

2. Below is the relationship between gear ratio (speed ratio) and

output speed for a pair of gears.

From the equation, when gear ration increases, the output speed will decrease and vice versa.

Below is the relationship between gear ratio and torque for a pair of gears. A gear's transmission torque changes as it increases or decreases speed. Generally, by increasing gear ratio, the output speed will decrease and a small torque at the input side is transmitted as a larger torque at the output side.

Using equations, as gear ratio is equal to the output torque over the input torque, but increasing gear ratio, output torque increases.

3. Below are the proposed design to make the hand-squeezed fan

better:

To begin, lets see what flaws the hand-squeezed fan we had during the practical had.

From the video, the fan is very unreliable as the handle does not smoothly go in and out when squeezed and retracted. This is due to the inner mechanism.

When the end of the arm reaches the furthest and closest point to the opening, it would get stuck and the arm would have difficulty moving up or down.

Proposed Design Change:

To make the fan more reliable, the friction points in the fan can be lubricated with oil to reduce the friction between contact surfaces and hence allow the gear to spin more easily. The arm attached to the input gear can also be thicker so that the force applied when the trigger is squeezed can be more evenly spread across a larger area.

4. Below are the description on how my practical team arranged

the gears provided in the practical to raise the water bottle.

a. Calculation of the gear ratio (speed ratio).

Total Gear Ratio: (40/30)(40/20)(40/12)(40/40)(30/12)(20/30)(40/30)= 11.852

b. The photo of the actual gear layout.

c. Calculation of the number of revolutions required to rotate the crank

handle.

200 mm / circumference of output gear = 20/2 x pi x 2.2cm = 1.446863119

Number of revolutions = 1.446863119 x (2 x pi x 2cm) = 18.18

d. The video of the turning of the gears to lift the water bottle.

5. Below is my Learning Reflection on the gears activities

Overall the practical was one of the most enjoyable practical sessions to execute, along side the cardboard fabrication practical during ICPD. However, the calculations did damper the mood a little bit as we had struggled with it as it was the first time we are learning about gears in depth, and hence overshot the practical duration.

For the first activity, in hindsight, I think my group should have made the gear ratio as small as possible. During the practical itself, we were told that trying to get the largest gear ratio possible was the correct method. However, I found it very strange as having the largest gear ratio would mean that the output gear would have very low torque, which indeed led to our group having trouble lifting the bottle up 20cm off the floor. I think the most time consuming part of the practical itself was assembling our gear transmission on the provided board. As we had made changes to the transmission as the practical progressed, we constantly had to remove the gears which took a lot of time as the bolts were very difficult to unscrew. One of our group members was also not present, which made each present member bear more tasks. Our gear transmission was also very unstable as the bolts provided were not long enough to go through the entire width of the gear which was the main contributor in our inability to lift the bottle over 20cm off the ground.

For the second activity, assembling the hand held fan was not an issue, however, actually using it was difficult. It was extremely unreliable as when I have squeezed the trigger, the fan would spin, but retracting the trigger was very difficult, unless I carefully moved the arm itself. The fan itself also did not attach to the output gear very well and I had to sand it down in order for it to fit. When my group recorded the video of me using the fan in slow motion, I did not squeeze the trigger with my full strength as I was worried the fan blade would fly off.

The takeaways for this practical have been invaluable. The use of gears extends beyond chemical engineering as is a basic knowledge all engineers need to have, similar to Arduino programming, AutoCAD and Excel. I hope to put my newly acquired knowledge to use for my CPDD assignment, capstone project and hopefully in the industry as well.

Comments